Hi.

I guess this is a pretty broad question with a hell of a lot of variables.

Let me run you down on my spec first

1.8T k03s running Audi TT BAM management

82mm 9.25:1 JE forged pistons with IE rods

AGU head with large port inlet

k03s turbo with ported manifold - stock actuator

Forge supersize dump valve - recirc

Custom free flow 2.5" pipework into a large core intercooler

AGU coilpacks

All the N valves removed for dump valve, evap, sai ETC.

3" TIP with large foam filter

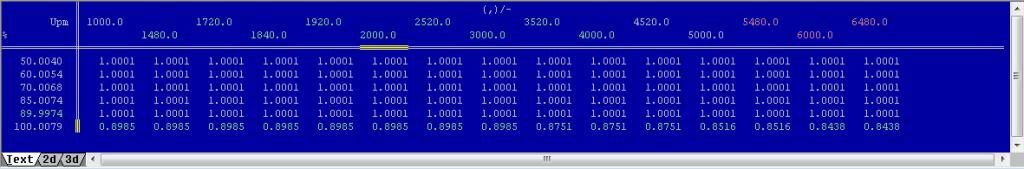

At the minute, im requesting fuel as below through lamda, and using BTS as my EGT enrichement protection map.

At the moment, it seems alright on a k04 standard map, 10psi was pulling 160g/s with stock fuel and timing, but some CF's

Now ive tried to raise the load through LDRXN to mid 160s and that gives me about 15psi according to my boost gauge which appears bang on.

Only issue Im having is when in high gears, low RPM, high load situations where the ECU drops into 'soft limp' mode and limits me to 5psi until I release throttle and press it again.

Ive tried copying the KFMLDMN maf lower diagnosis table over from a 032 HN tune and that sorted all gear up until 6th where it would occasionally drop into limp.

Has anyone got any ideas what else could be causing it to drop into soft limp?

Attached is my 'latest' file which im using today. No CF's it appears, just the occasional soft limp I describe above. Holding 15psi pretty much throughout the revs.

Any advice would be appreciated.