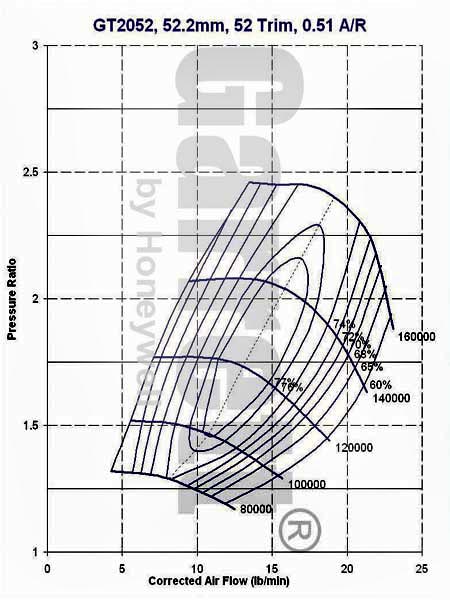

Thanks. I'll say this when looking at compressor maps: they are corrected for sae or at sea level. Once you change P1, you have to recalculate/recalibrate the x-axis flow. The axis values will shift left or right depending if you are correcting for a higher or lower P1. The big turbo is increasing the P1 for the small turbo map. Single turbos, it's atmosphere or whatever pressure pre-compressor which may be lower due to filter restriction.

mcorr = m*sqrt(T2/T1)/(P2/P1)

mcorr = Corrected Mass Flow (new x-axis)

m = Actual Mass Flow

P1 = STP Reference Inlet Pressure

P2 = Compressor Inlet Pressure

T1 = STP Reference Inlet Temperature (*K)

T2 = Compressor Inlet Temperature (*K)

Course the pain is that not every turbocharger manufacturer's "corrected" conditions are the same... Hence why some measure in mass flow rather than corrected volumetric flow, since that depends on the environment.

In this situation - taking into account what I said above - if the engine is capable of consuming 25lb/min, if you make the compressor inlet temperature 40*C and pressure 2bar(abs) on the inlet, when you correct the mass flow assuming, it's equivalent to that turbocharger moving 18.42lb/min.

25*sqrt(313/288)/(2/1) = 18.42lb/min

I'm fairly sure I'm correct here... Issue being you run up against the choke line quite quickly at low PR - look at the trend of the compressor shaft speed lines, at higher airflow, even at lower pressure, you're tending towards higher and higher compressor shaft speeds and into choke...