jpurban

Jr. Member

Karma: +5/-0

Offline Offline

Posts: 40

|

|

« Reply #15 on: June 19, 2018, 10:33:57 PM »

|

|

|

Can you feel it while driving?

Absolutely, especially when cold. It isn't violent or anything. The throttle just goes limp/numb and the car doesn't respond for a split second or so. You can feel the stumble in your butt dyno. ;-) |

|

|

|

|

Logged

Logged

|

|

|

|

jpurban

Jr. Member

Karma: +5/-0

Offline Offline

Posts: 40

|

|

« Reply #16 on: June 19, 2018, 10:38:40 PM »

|

|

|

*** Update -- Pushed the WFRL changes too far and made matters worse. Slight surging under constant acceleration as I transitioned from one load steo to another. Logs show the lambda bouncing around more, confirming that my changes weren't the right ones. At this point, I'm going to revert to stock values and start again. *** Alright... I've taken another run at my WFRL. This time I've examined the derivatives of WFRL because the FR says the curve should be smooth.

I tried this out this morning and it helped some, but the throttle response was definitely smoother. I'll need to take it further... (removing the dip described below).

Anyway, just wanted to ask if anyone else has reviewed the derivatives of their OEM WFRL curves. My problem ocurrs between 30% and 60% load, which is also where the WFRL derivative has a "dip" in it. Do the AUDI OEM WFRL curves have the same dip?

My thinking is that the 1st derivative slope should be steep to start and then gradually flatten out.... clearly, my OEM curves don't do that. And the second derivative is really telling... Note the OEM curve is very inconsistent from point to point.

So, why did the OEM have these weird undulations in the 1st derivative? Does the cam overlap and valve lift affect wall film? I'm not sure...

|

|

|

|

|

Logged

Logged

|

|

|

|

|

prj

|

|

« Reply #17 on: June 20, 2018, 12:48:04 AM »

|

|

|

ohhhh, SUPERMEGATUNER, I like the sounds of that lol. Actually, my post was right on point if you cared to look at the title of the thread "leaning out on cam advance" AND my point about parking the exhaust cam for transient response is also an excellent point that no one else has ever raised to my knowledge.

You'll also note that I also mentioned the wall wetting as being the root cause of the lean spike (and gave you credit for being the first one to point it out (although I did know it in advance of reading your post).

Further, parking the exhaust cam on an FSI engine also has the advantage of eliminating EGR which is the cause of most, if not all of the carbon buildup on the intake valves that plagues that engine series. Again, a point that I have yet to see anyone raise around here.

Dude, this car is not FSI nor does it even have adjustment on the exhaust cam. No one cares. I'm willing to keep working on ESUK adjustments, but could benefit from your experience. First question... Do you have to have a dyno to effectively update ESUK for new injectors? Yes, see below  Second... Do you disable KFBAKL/KFVAKL (Set to 0) when trying to tune WFRL, as the FR instructs? I guess simply want to know your process for ESUK tuning... Any key steps? I kinda mash stuff around until it's right. I don't do it as the FR instructs. WFRL makes global changes, KFBAKL/KFVAKL are more precise. Try KFBAKL.... I don't remember anymore what I changed in the end. And yes, it is normal that it drops to almost nothing, because the stock injectors are perfect for the application, whatever you are using now isn't though (as it was in my case). Try setting the 90 degree to about the same as the 45 degree and test what happens. Warmup stuff - KFWWL? I don't have a great deal of Porsche cal experience, some maps are different / called different in ME7.8. Btw for KFBAKL to have an effect there has to be some sort of load gradient or throttle gradient during the actual change. If load is fairly static, then it's not gonna do much. |

|

|

|

« Last Edit: June 20, 2018, 12:50:33 AM by prj »

|

Logged

Logged

|

|

|

|

Mikhail

Full Member

Karma: +2/-4

Offline Offline

Posts: 136

|

|

« Reply #18 on: June 20, 2018, 03:21:09 AM »

|

|

|

I kinda mash stuff around until it's right. This suprises me, same method I use but don't usually get quite right. I don't know what you are talking but what about the turbo enrichment which I don't have because originally NA and due that slight lean when boost rises? |

|

|

|

|

Logged

Logged

|

|

|

|

|

prj

|

|

« Reply #19 on: June 20, 2018, 05:31:33 AM »

|

|

|

This suprises me, same method I use but don't usually get quite right. I don't know what you are talking but what about the turbo enrichment which I don't have because originally NA and due that slight lean when boost rises?

Such thing like "turbo enrichment" does not exist. You have problem with hardware, car or incorrect mapping. Probably all of it at the same time. Please keep this on topic guys, we're talking about Porsche 996TT here. Thank you. |

|

|

|

|

Logged

Logged

|

|

|

|

jpurban

Jr. Member

Karma: +5/-0

Offline Offline

Posts: 40

|

|

« Reply #20 on: June 20, 2018, 07:04:29 PM »

|

|

|

An update...

I reset the ESUK transient comp tables to stock values and logged today on the way to work. There was an accident and traffic was horrible, clutching stop and go for several miles. That sucked, but it gave me lots of low speed, low load logging, which is exactly what I needed.

Here's what I noticed... Most of my lean outs occurred when slowly accelerating AFTER a slow rolling deceleration (no throttle) with NO gear change/clutching -- even with a fully warm engine. When decelerating in gear, the RL falls well below idle RL (even with DFCO disabled) -- down to a range of 15% to 18% RL. Once I accelerate slightly -- no cam change -- my lambda spikes to 1.1 or higher and the car stumbles/hesitates (but does not stall - so the issue isn't bad).

Important learning #1... Since I don't have much problem accelerating from a stop and my RL doesn't dip below 18% (usually) when doing so (a different load step range), I have to suspect my WFRL value between 12 and 18. Question... If I wanted to apply a fix to this range only, what is the best way to make that change? Lower the value in WFRL at 12 and below? Or, raise points 18 and above? If raising 18 and above, how do you keep from disturbing the other ranges? This may sound like a dumb question, but I'm really asking if it is more important to maintain the percentage difference or the absolute value difference of the steps you don't want to change.

Important learning #2... Decelerating in gear (no throttle) drives the RL down to the values in KFRLMN/KFRLMNSA. Knowing this -- and the issues I have below 18 RL -- one solution could be to avoid the range below 18 by simply raising KFRLMN to some value above 18, but still below idle RL.

Since KFRLMN is a pretty easy solution, I'm thinking of changing it and then logging again -- ignoring the WFRL for now. If the majority of the lean out goes away with this change, I may not need to mess with WFRL since the rest of the load range (OEM values) felt pretty good today.

PRJ, looks like you have a nice dyno set up. That's an AWD dyno, right? What I'm really wondering though... How the hell do you keep it so clean?

Any thoughts? Anyone else increased KFRLMN in their tunes?

|

|

|

|

|

Logged

Logged

|

|

|

|

|

mister t

|

|

« Reply #21 on: June 20, 2018, 11:33:50 PM »

|

|

|

I kinda mash stuff around until it's right. Holy shit!!! we agree on something!!! Quick, go look out your window and tell me if you see four horsemen in the sky lol  Seriously though, cam adjustment of ANY type on a system as dynamic as a 4 stroke engine with constant torque demands (with or without a turbocharger) is a black art. Although PRJ is correct in stating that your question doesn't really involve cam phasing, I'm gonna add my 2 bits since I'm on my soapbox. Speaking from my experience, I've literally spent hundreds, if not thousands of hours looking through my datalogs to see how mass airflow and measured load respond to cam phasing. The best way I can articulate how cam adjustment works in practice is thus; Any engine will have natural resonance peaks in accordance with its' hardware (exhaust, intake, throttle, etc...). Where cam adjustment shines is that it allows you 1) maximize the torque from those natural resonance spots, or to 2) eliminate the dips in the torque curve. Basically just move the cams around the spots that you want magnified or filled and eventually you'll come up with a superior torque curve than you would with a fixed cam. With NATURALLY ASPIRATED engines, the way I view it is that the airflow is dynamic, To fill in a hole, I dial in advance (overlap) in a smooth, radiused drop-off. However, you eventually 'bottom out'. To 'recharge' the airflow, I quickly pull the cam timing back up towards lobe separation over 200 RPM or so. Then, I start dialing advance back in. Rinse lather repeat. Most (if not all) of my cam timing sweeps at WOT have a smooth, saw tooth look to them. I'll try and post some pics up to show what I mean. While there is some debate as to whether or not changing the OEM calibrations on a stock vehicle will do you any good, I am of the opinion that you can improve on them performance wise. Reason being, is that you're not concerned with emissions and trying to make everything as smooth as possible for the 'average' driver. Then, once you start changing the intake/exhaust and alter the VE of the engine, getting the cam adjustment dialed in is a MUST!!!! I cam promise you that 95% of tuners don't mess with the cams on naturally aspirated Audi engines. Want proof, just look at their dyno plots, if the SHAPE of the tirque curve remains the same, they only added timing and touched up the fueling. Anyway, I know this is off topic, but I've just spent the last 4 hours reading SAE and Academic papers on the subject and thought I'd take the time to drop some nollij on 'yall  |

|

|

|

« Last Edit: June 20, 2018, 11:53:16 PM by mister t »

|

Logged

Logged

|

|

|

|

|

mister t

|

|

« Reply #22 on: June 21, 2018, 12:06:40 AM »

|

|

|

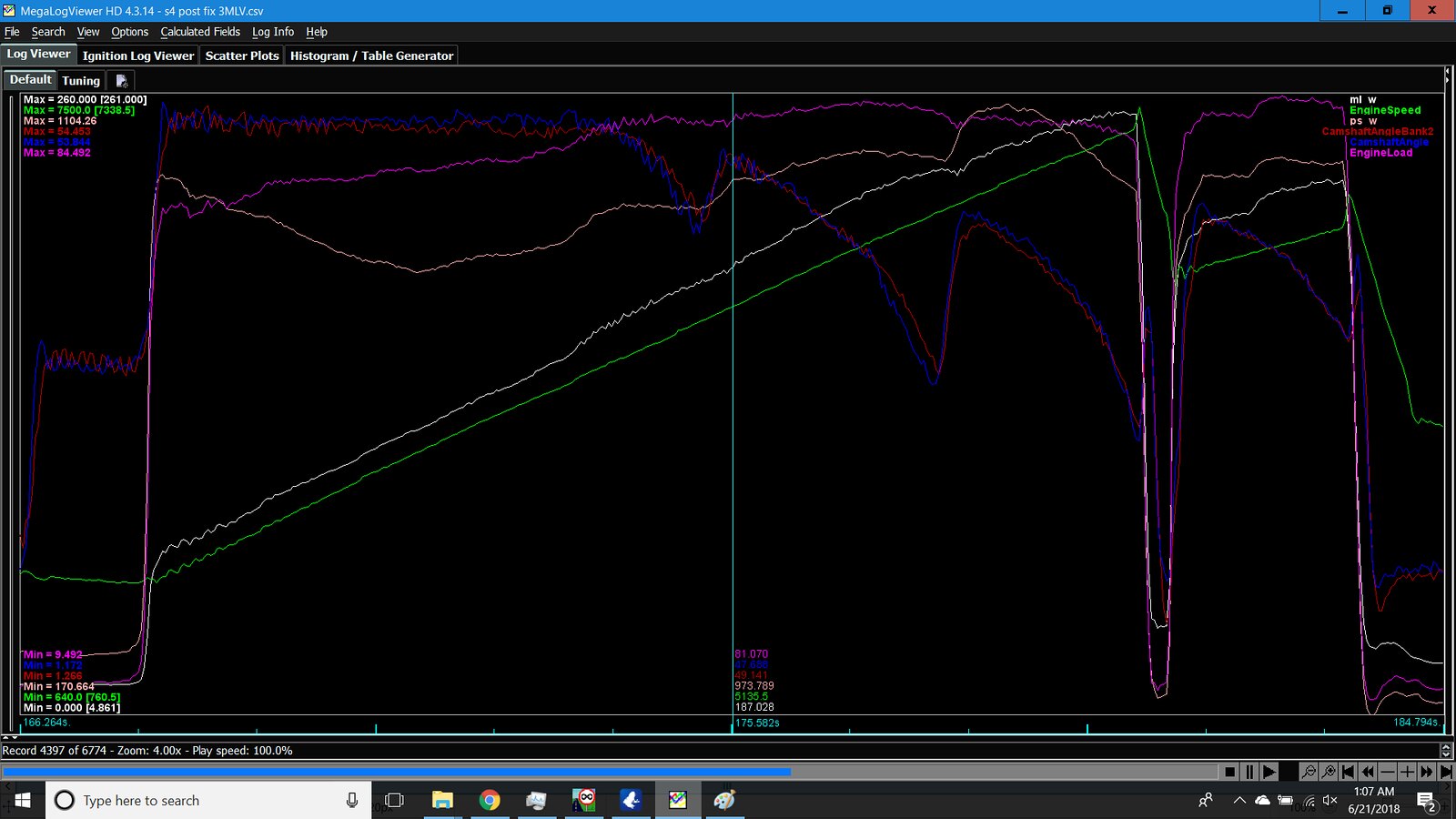

Here's a pic of one of my latest logs. Notice how the airflow picks up along with how the cams move after 4000 RPM and stays just about dead straight to 7000 RPM? Same with measured load (pink line). Measured load (at least with N/A engines) is a carbon copy of the shape of your torque curve. Here, it only varies by about 5% from 2000-7000 RPM!!!  Finally, the other light line is _ps (manifold pressure). It drops a bit past ambient (898 mbar) then after 4000, it goes past 1000 mbar for the rest of the pull. Anyone in the know care to say why that is? I should also note that this S4 is modified to the hilt. Headers, dual X pipe, 3.5 silicone intake, re-engineered intake manifold (w 'mid length' runners), shaved half shaft throttle body, all on my own tuning file... Driving wise, the car almost feels slow because the torque curve is so flat and the acceleration is so linear through 3rd, 4th etc...  560A S4 dialed in 560A S4 dialed in by zimbu themonkey, on Flickr |

|

|

|

« Last Edit: June 21, 2018, 12:23:55 AM by mister t »

|

Logged

Logged

|

|

|

|

|

prj

|

|

« Reply #23 on: June 21, 2018, 02:14:29 AM »

|

|

|

Since KFRLMN is a pretty easy solution, I'm thinking of changing it and then logging again -- ignoring the WFRL for now. If the majority of the lean out goes away with this change, I may not need to mess with WFRL since the rest of the load range (OEM values) felt pretty good today.

KFRLMN might have some other implications... Check your TEMIN also, that it's not pegging the injectors. PRJ, looks like you have a nice dyno set up. That's an AWD dyno, right? What I'm really wondering though... How the hell do you keep it so clean? It was obviously cleaned for the photos  And yes, AWD with adjustable wheelbase and toggleable front-to-rear lock (required for the 996TT). But we try to clean it every now and then and keep it looking fresh. |

|

|

|

|

Logged

Logged

|

|

|

|

zweistein

Newbie

Karma: +2/-0

Offline Offline

Posts: 19

|

|

« Reply #24 on: June 21, 2018, 04:13:11 AM »

|

|

|

Does the lean point happen always a certain MAF flow values?

As you changed intake geometry,e.g. different compressor wheel,maybe KFHFM or the relative compensation tables are out offerte tune.

Andreas

|

|

|

|

|

Logged

Logged

|

|

|

|

jpurban

Jr. Member

Karma: +5/-0

Offline Offline

Posts: 40

|

|

« Reply #25 on: June 21, 2018, 09:07:55 PM »

|

|

|

Andreas, I think you're essentially asking if my steady state fuel trims are good. If they weren't, then I'd need to focus on TVUB/KRKTE to dial in RKAT/FRA in rough terms... and then KFHFM for any lean/rich spots across the MAF spectrum... then FKKVS/KFKHFM across both engine speed and TE/MAF. Working from broad to narrow, so to speak. Right? I've spent hours and hours learning that process, logging, trial and error, etc. All the stuff I'm sure many here have done as they climbed the learning curve. I think my steady state fueling is as good as I can expect. I've attached a screenshot of my steady state lambda error, showing that I'm +/-3% across the "part throttle" street driving spectrum. The error shown INCLUDES LRA adjustments (as part of the error) so you have an idea of the quality of my steady state tune -- I'm not relying on LRA to save my ass. I have to pause to give some props... As for the "dynamic" lambda control at higher loads/airflow near WOT, Bosch ME7 is f'ing awesome. I've had my car for 5 years and I'm still amazed at the accuracy/control of the widespan O2 closed loop control at WOT. The ME7 ain't your daddy's Holley 4 barrel carb on his '69 Chevelle. ;-) All this said, I hope I've convinced you that I've done the necessary homework to be on the ESUK tuning step. I'm at the point of turning to ESUK and NWS to find a solution to my transient lean/rich conditions. I really didn't want to tackle this additional step, but I don't feel I have a choice since some of my transient lambda errors swing from +25% rich (decel) to -25% lean (accel) in the span of a few seconds. So, I'm going through the pain, failures, frustration of dealing with ESUK as a newbie. John Does the lean point happen always a certain MAF flow values?

As you changed intake geometry,e.g. different compressor wheel,maybe KFHFM or the relative compensation tables are out offerte tune.

Andreas

|

|

|

|

|

Logged

Logged

|

|

|

|

jpurban

Jr. Member

Karma: +5/-0

Offline Offline

Posts: 40

|

|

« Reply #26 on: June 21, 2018, 10:25:30 PM »

|

|

|

*** Update - Another day of logging ***

Tested changes today...

1. Smoothed out WFRL from OEM. Overall WFRL has the same span as OEM, but I smoothed out the slope changes across load steps. First step to refining WFRL.

2. Increase KFNW slightly at low engine speed to raise cam changeover to improve driveability with imperfect transient adjustments

3. Raised KFRLMN to 19.5% minimum (just below warm idle, no a/c load) to provide additional margin to transient errors

Good news: I really like the improvement in throttle response when underway, which I attribute to the WFRL update, especially the increase around 30 to 40%. Also, higher cam change point kept stuttering to a barely noticeable level, but it is clearly still there as the logs show. Cam changeover shift confirms lean out is poor transient response - not cam changeover. See the log to watch the rich/lean decel event play out while the cam stays in overlap position.

Bad news: Raising KFRLMN out of the 12 to 18 load step range of WFRL did NOT have the desired effect. The big issue of rich decel to rolling idle leading to idle/accel lean out is still present.

Analysis at this point... Throttle off decel at mid-level, cruise load drops to RLMN. During decel, mixture goes extreme rich (sensor limit, about 0.75) initially, then leans out. This suggests one of the following corrective actions:

1) Increase WFRL over load range to increase enleanment on decel. This doesn't seem ideal because the accel transient seems pretty good when not following a decel.

2) Increase short term portion of decel enleanment (KFAVAK) to shift enleanment to address initial richness and simultaneously reduce late decel lean. This seems to make the most sense as a next step. Reducing the long term enleanment, that can effect accel that immediately follows, may be more of my issue than pure accel enrichment. I've included a log sample that shows a decel to rolling idle that illustrates the point.

3) I don't think it makes sense to raise total decel enleanment (KFVAKL) until the short/long split is corrected.

Sounds like a plan, but... A review of KFAVAKL/KFAVAK reveals that the short term factor is already pretty high at 0.30+, above the FR suggest value of 0.25. And... The KFVAKL values are low relative to the FR suggested values. Perhaps that doesn't matter, but the FR says if you stray too far from the suggested values, something is probably wrong with WFRL/ZUKK/DUKK/etc. So, I'm a little lost at the moment regarding the next step.

I need to stew on this a little more.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

prj

|

|

« Reply #27 on: June 21, 2018, 11:23:56 PM »

|

|

|

You will need to bump KFVAKL a lot higher than what is said in the FR, maybe 5 times as high, when you have injectors not made for the application...

Also, did you make sure TEMIN is low enough?

|

|

|

|

|

Logged

Logged

|

|

|

|

|

mister t

|

|

« Reply #28 on: June 22, 2018, 12:53:11 AM »

|

|

|

I came across this information in a Porsche training document. It gives some general information about cam adjustment in the 996 turbo, 997 turbo and GT3 models. Hope it helps  |

|

|

|

|

Logged

Logged

|

|

|

|

zweistein

Newbie

Karma: +2/-0

Offline Offline

Posts: 19

|

|

« Reply #29 on: June 23, 2018, 03:27:33 AM »

|

|

|

Fuel trim is always a very slow adaption of the mixture (in the range of 0.75 to 1.25 where 1.0 is no correction). So at a steady engine speed after let s say 0.5 seconds the fuel trim will adjust to correct lambda. Long term fuel trim is even slower.

So it is too slow for your transient lean condition.

Basically to measure HFM calibration the whole lambda - autoadjustment of ME7 is a problem.

I usually set all KFLF to 0.9 and also KFLBTS and LAMFA to 0.9.

I found that in this way the lambda regulation is turned off (at least for several seconds at constant rpm and throttle) as the target is too far away from 1, see FR somewhere.

Then I do a simple log drive with steady slow acelerations at different throttle plate angles.

From the log I then fill an excel table where I prepared the x and y points to correspond to the KFHFM table. Y - yalues are measured lambda (I use my own lambda sensor). It is a wise idea to write yourself a little program that does parse the log data .

Ideally all y - values should be lambda 0.9 (they are not in my screenshot as it is taken from a different setup , no time to search through all my measurements.)

Where you see differences, correct the KFHFM table and try again.

Good luck

Andreas

|

|

|

|

|

Logged

Logged

|

|

|

|

|