|

majorahole

|

|

« Reply #15 on: March 01, 2013, 10:33:37 AM »

|

|

|

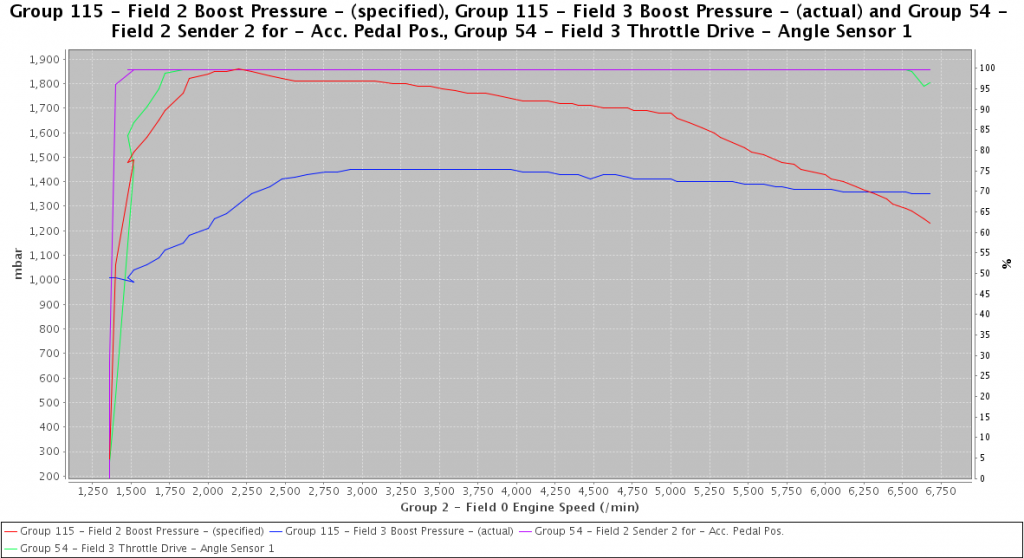

so with the help of Rarak, i decided to do what I wanted to do initially and that was to copy across the PID maps from the ed30 GTI which is K04 in stock form and this has smoothed out the boost considerably. I forgot to enable turbo mode in vcds so the resolution isnt so high but you can see the difference. I will do more logging this evening to verify thats its better but the car feels smoother.

isn't that what you wanted to do initially?? |

|

|

|

|

Logged

Logged

|

|

|

|

|

airtite

|

|

« Reply #16 on: March 01, 2013, 10:39:20 AM »

|

|

|

isn't that what you wanted to do initially??

exactly!! |

|

|

|

|

Logged

Logged

|

|

|

|

fredrik_a

Full Member

Karma: +25/-0

Offline Offline

Posts: 221

|

|

« Reply #17 on: March 02, 2013, 11:01:43 AM »

|

|

|

In my experience, requesting far more boost (low revs) than the turbo can produce will sometimes mess up the boost control somewhat. Try to request sane levels of boost. You are requesting 1.1 bars of boost@2.100 rpms, but (if the log is somewhat close to normal behaviour) this is a boost level that isn't reached in reality until a thousand rpm's later. Perhaps the high boost at low revs can be forced to appear during a static dyno pull with long duration before taking the measurement, but on the street it doesn't seem like it. I would try to adjust "requested" to better correlate with what is possible as it might improve the behavious even further.  |

|

|

|

|

Logged

Logged

|

|

|

|

|

|

fredrik_a

Full Member

Karma: +25/-0

Offline Offline

Posts: 221

|

|

« Reply #19 on: March 02, 2013, 12:16:15 PM »

|

|

|

Not only that... Even if you disable boost deviation monitoring, the PID controller will be unneccesarily stressed when working way off target. |

|

|

|

|

Logged

Logged

|

|

|

|

|

nyet

|

|

« Reply #20 on: March 02, 2013, 01:07:14 PM »

|

|

|

I and P are both maxed during spool anyway...

The only issue is I limit trims... which you can't fix by lowering req boost.

You have to move the RPM ranges around a bit for very laggy turbos so the trimming doesn't happen at low RPMs.

|

|

|

|

|

Logged

Logged

|

ME7.1 tuning guideECUx PlotME7Sum checksumTrim heatmap toolPlease do not ask me for tunes. I'm here to help people make their own. Do not PM me technical questions! Please, ask all questions on the forums! Doing so will ensure the next person with the same issue gets the opportunity to learn from your ex

|

|

|

|

airtite

|

|

« Reply #21 on: March 03, 2013, 06:41:50 AM »

|

|

|

In my experience, requesting far more boost (low revs) than the turbo can produce will sometimes mess up the boost control somewhat. Try to request sane levels of boost. You are requesting 1.1 bars of boost@2.100 rpms, but (if the log is somewhat close to normal behaviour) this is a boost level that isn't reached in reality until a thousand rpm's later. Perhaps the high boost at low revs can be forced to appear during a static dyno pull with long duration before taking the measurement, but on the street it doesn't seem like it. I would try to adjust "requested" to better correlate with what is possible as it might improve the behavious even further.  sure, but this was on the stock file and spool on the k04 shouldnt be far off the k03 so not sure if it was a boost request issue as much as what it was a boost control issue either way the car is much better now. I am however having a surging issue in the higher gears in the upper rpm under load especially uphill I will try and get some more logging in place now but at least I am moving forward. |

|

|

|

|

Logged

Logged

|

|

|

|

|

airtite

|

|

« Reply #22 on: March 03, 2013, 06:44:13 AM »

|

|

|

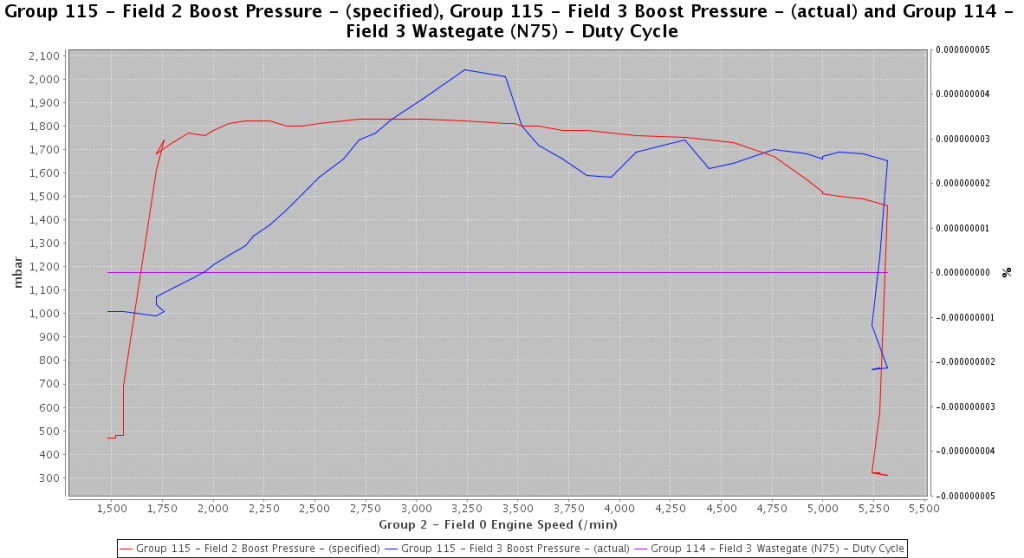

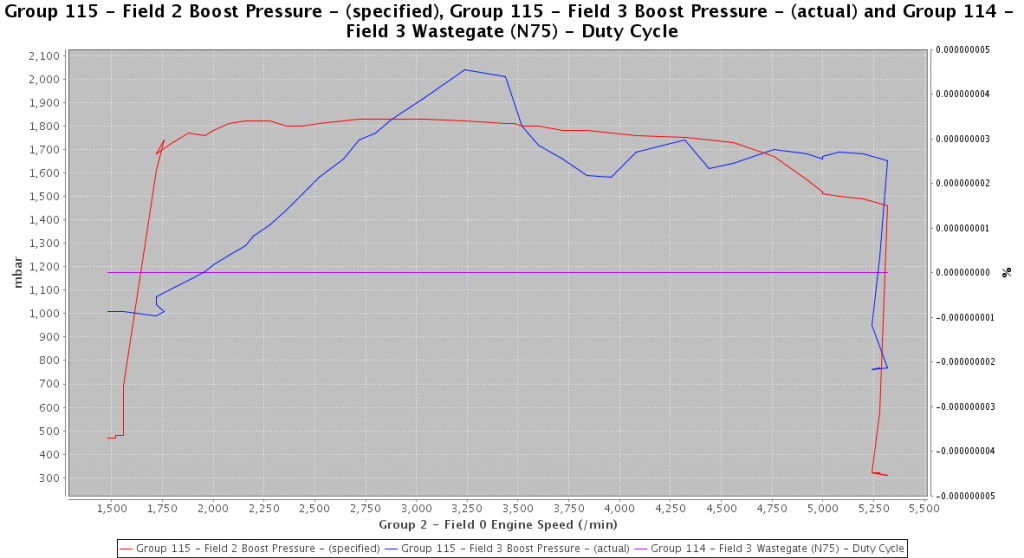

the deviation code I was getting was positive deviation but not underboost it was an overboost condition mainly caused by actual exceeding requested in the upper rpm even though wgdc was low |

|

|

|

|

Logged

Logged

|

|

|

|

|

matchew

|

|

« Reply #23 on: March 03, 2013, 07:29:06 AM »

|

|

|

Punctuation might help you.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

airtite

|

|

« Reply #24 on: March 03, 2013, 10:01:27 AM »

|

|

|

Punctuation might help you.

better  thanks for your valuable input The deviation code I was getting was positive deviation, not underboost it was an overboost condition. Mainly caused by actual exceeding requested in the upper rpm even though wgdc was low

|

|

|

|

|

Logged

Logged

|

|

|

|

|

airtite

|

|

« Reply #25 on: March 09, 2013, 05:58:13 AM »

|

|

|

just to dig this up again, I wanted to make 100% sure that my wastegate actuator was correctly adjusted so I ran a vacuum line straight between the turbo outlet and the actuator and left the n75 electrically connected so the ecu would think it was still connected and this was the result, cracking pressure is 6.8psi and peddle position and throttle plate angle both at 100%.. so actuator adjustment is 100% and this is purely a PID issue, still need to work out why using the PID calibration method as described in here doesnt work but I am sure I will eventually figure it out.  |

|

|

|

|

Logged

Logged

|

|

|

|

|

nyet

|

|

« Reply #26 on: March 09, 2013, 09:30:00 AM »

|

|

|

That doesn't explain this, unless VCDS is logging the wrong variable with CWMDAPP = 8 and KFLDRAPP = 0 AND you have the definition for CWMDAPP/KFLDRAPP wrong  Or your N75 is bad, or it is plumbed wrong. |

|

|

|

|

Logged

Logged

|

ME7.1 tuning guideECUx PlotME7Sum checksumTrim heatmap toolPlease do not ask me for tunes. I'm here to help people make their own. Do not PM me technical questions! Please, ask all questions on the forums! Doing so will ensure the next person with the same issue gets the opportunity to learn from your ex

|

|

|

|

airtite

|

|

« Reply #27 on: March 09, 2013, 10:21:39 AM »

|

|

|

That doesn't explain this, unless VCDS is logging the wrong variable with CWMDAPP = 8 and KFLDRAPP = 0 AND you have the definition for CWMDAPP/KFLDRAPP wrong

I will double check my definitions. Or your N75 is bad, or it is plumbed wrong.

I double checked plumbing and its doing the same thing with 2 n75s both of them cant be bad. |

|

|

|

|

Logged

Logged

|

|

|

|

|

airtite

|

|

« Reply #28 on: March 11, 2013, 11:37:05 PM »

|

|

|

That doesn't explain this, unless VCDS is logging the wrong variable with CWMDAPP = 8 and KFLDRAPP = 0 AND you have the definition for CWMDAPP/KFLDRAPP wrong  Or your N75 is bad, or it is plumbed wrong. None of the above, my definitions are correct. N75 swapped and triple checked plumbing. Anything else you can think of? |

|

|

|

|

Logged

Logged

|

|

|

|

baldy

Newbie

Karma: +0/-0

Offline Offline

Posts: 2

|

|

« Reply #29 on: April 13, 2013, 05:41:02 PM »

|

|

|

Did you ever manage to get this figured out? I'm having the exact same issue on my B7 A4 with a S3 K04. Only difference is my wastegate cracks at 10 psi vs your 7 psi.

|

|

|

|

|

Logged

Logged

|

|

|

|

|